Highlights

State of the Art

Dependable, accurate, reliable, and customizable. DrumTronic is ideal for a simple bitumen and aggregates blending-only application or comprehensive total plant control. Its software adaptability is paired with a modular hardware design made of one or many of the same electronic I/OS boards. It comes with an industrial-grade PC, security and redundancy, remote access, and support. It is complemented with Android and Apple apps and a beautiful graphic signature. Did we say it is very reliable? DrumTronic gives you the control and the peace of mind.

Highlights

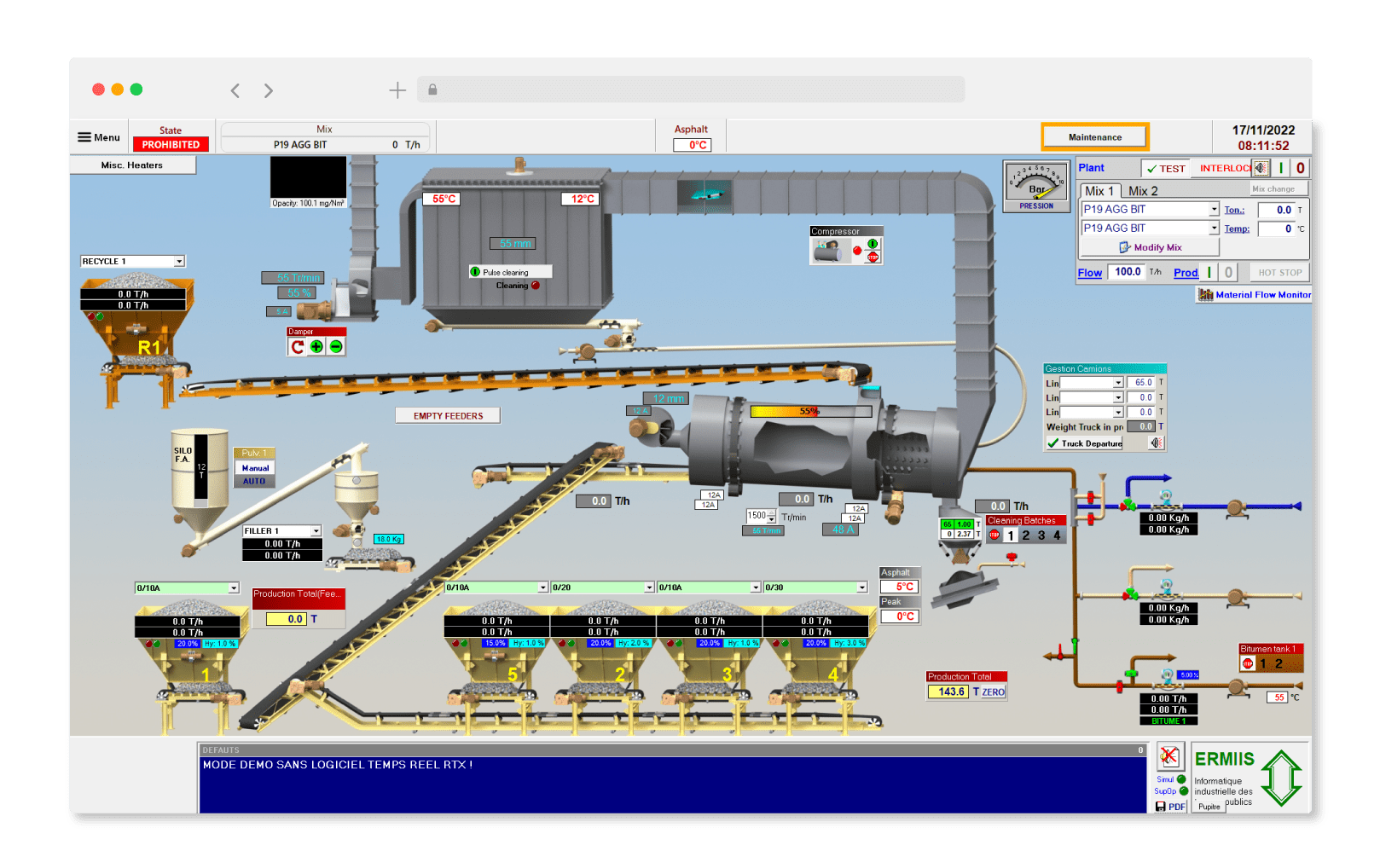

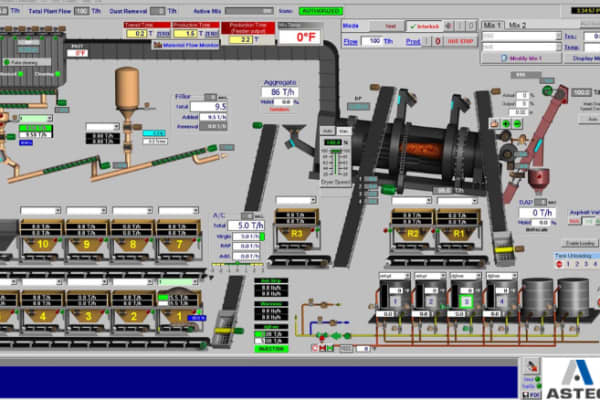

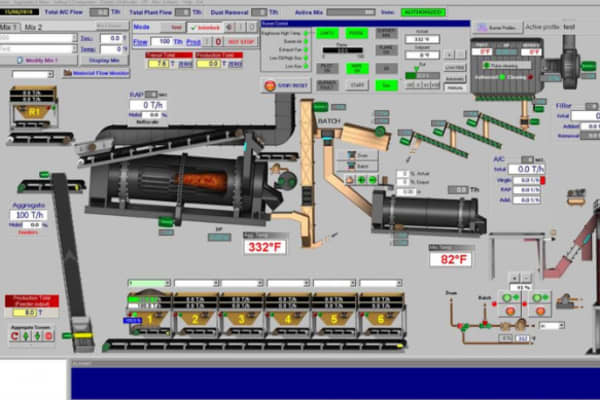

Clearly See Your Operations

The human interface has been thoroughly designed in collaboration with actual operators. The layout of information allows for a quick understanding of the overall workings. Delays and timing, for example, are displayed over a graphic representation of material flow and plant layout. These types of details help to prevent errors and misinterpretation. Large arrays of numbers are avoided in favor of clear symbolic information.

Highlights

Always In Control

The operator remains in control, and the process can be stopped and resumed anytime, while direct control of motors is always possible. The software can control silo storage, including complex conveying layouts, ensuring a clean and precise change of silo following a mix change. For combo or hybrid asphalt plants requiring management of towers, individual batches, and large drum mixes, ASTEC has solutions to visualize your operation for ultimate control. See the BatchTronic product page for more information on batch plant control. Our automation software can also be linked to our TicketManager so managers can see a high-level overview of totals, consumption, and inventory usage.

Quick Tour

Specifications

- Up to 30 feeders, volumetric or weight, with or without encoder feedback, loader signaling light, material flow sensor and optic bin level sensor, and vibrator control.

- Calibrated with up to 30 materials with main aggregate belt scale or truck, wet or dry calibration curves, archivable and printable calibration report with linearity graph with up to 10 points per feeder/material couple.

- Feeders run either in auto-on-user-adjustable PID speed, flow control loops, or in manual with an operator-adjustable set point for feeder emptying or manual override.

- LiveBin application on Android and Apple tablets and smartphones gives the loader operator relevant real-time information about the current mix, next mix, currently used feeders, flow sensors, etc.

- Up to 10 Belt scales: Virgin Aggregate and RAP plus 8 auxiliary belts

- Flow monitoring from direct flow signal or calculated via speed times weight

- Up to 4 fully automated and configurable calibration points per belt scale

- Fully automated and configurable belt scale tare procedure

- Multi-level calibration backup/restore with archived, viewable, and printable reports

- Up to 3 asphalt product lines and 20 asphalt product materials

- Volumetric type, with or without encoder feedback or mass flow signal type

- Automatic or manual material density calculations for volumetric systems

- Single/double encoder inputs for pump/meter correlation and backup

- Asphalt material flow detection

- Analog or increase/decrease pump control

- Calibration procedure for each pump/meter combination with simultaneous calibration of the asphalt meter and pump for redundant or backup control

- Fully automated procedure with archived calibration reports

- Asphalt pumps run either in auto on user-adjustable PID flow control loops or in manual with an operator-adjustable set point for material emptying or manual override

- Up to 4 independent mineral filler lines and 10 filler materials

- Additional single re-circulated bag house dust line

- Volumetric type, with or without encoder feedback

- Mass flow through weight depletion vessel

- Analog or increase/decrease control

- Given proper equipment, we can calculate bag house dust removal flow and adjust belt scale flow accordingly for better production control.

- Automatic through dryer negative pressure or manually controlled

- Analog or increase/decrease damper control

- Complete manual or automatic burner damper control (optional)

- Selectable burner temperature reference, exhaust gases, or materials

- Burner damper runs either in auto on user-adjustable PID flow control loops or in manual with an operator-adjustable damper opening

- Analog or increase/decrease control

- Note: The burner system must have a separate/external customer-supplied flame security interface.

- Configurable automatic conveying motors start/stop sequence

- Configurable production motors start/stop sequence

- Configurable hot start/stop sequence

- Mix changes with an operator-set mix timer

- Custom production screen adapted to reflect your plant

- Damped production rate change to prevent instability

- All elements accessible for on-screen operation

- Unlimited Alarm historical log

- Production totals and daily totals compiled from actual material flows

- Flexible report design tool allows for user-adapted reports

- Production inventories and material usage reports

- Calibration reports

- Real-time material flows and production rates

- Motor currents (given proper signals)

- Conveying element status (given proper signals)

- 3D graphical user Interface representing actual plant configuration

- Industrial plant computer running Windows® with RTX real-time subsystem

- I/O modules through 10/100Mb Ethernet on a TCP/IP-based protocol

- Each industrial module (XIO) has the capacity to acquire 64 Logic Inputs, 32 Logic Outputs, and 12 Analog Inputs (4 on base and two 4 inputs extension boards) featuring multi-range self-calibrating from 20mV to 10VDC (0-20, 4- 20mAdc external supply), 6 Analog 0-10V output (2 on base and two 2 output extension boards), 6/12 High-speed counting inputs (Quad/Single)

- The system is easily customized through multi-level user-accessible parameters

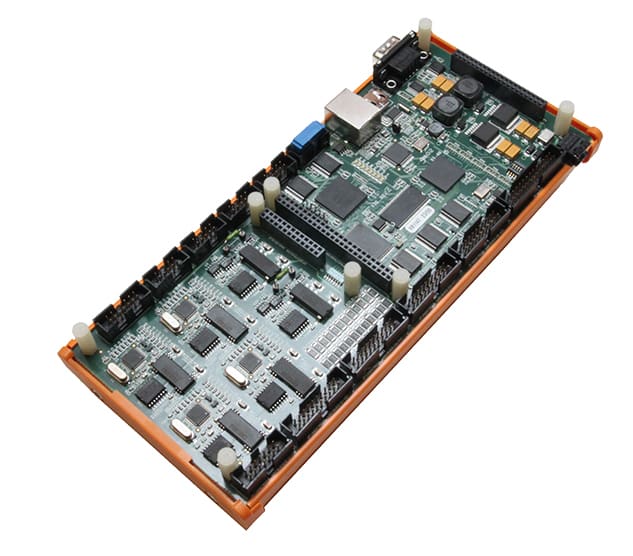

XIO Controller

Dedicated hardware for inputs & outputs

All our plant control systems' electrical inputs and outputs are handled through one or many instances of a single type of electronic board: The XIO. A small batch plant requires just a single one, while a very large drum plant may require upwards of 5 boards. Employing one type of I/O board means there is just one model to manufacture, stock, maintain, and support. We have deployed 1000s of them at 100s of plants on 4 continents. Learn more here.

The ASTEC Digital data suite, Connectivity Suite, brings together all of the digital offerings into a single standardized platform from ASTEC. Our intention and objective are to be a digital solution provider of choice. As our offerings evolve, we are committed to our Rock to Road customers. We vow to remain a customer-focused entity, developing durable solutions to help our customers on their journey.